Benefits of Using Brass in Automotive Manufacturing

In the early 20th century, the automotive industry saw a remarkable transformation as ingenious Americans, inspired by European innovations, began crafting automobiles with predominantly brass components. This trend, which marked the golden age of brass in automotive manufacturing, showcased the metal’s exceptional properties and set the stage for its continued use. At Sneh Metal Alloys, we understand the enduring benefits of brass parts in automotive applications. Here, we explore why brass remains a top choice for car manufacturers and highlight its significant advantages.

Exceptional Durability

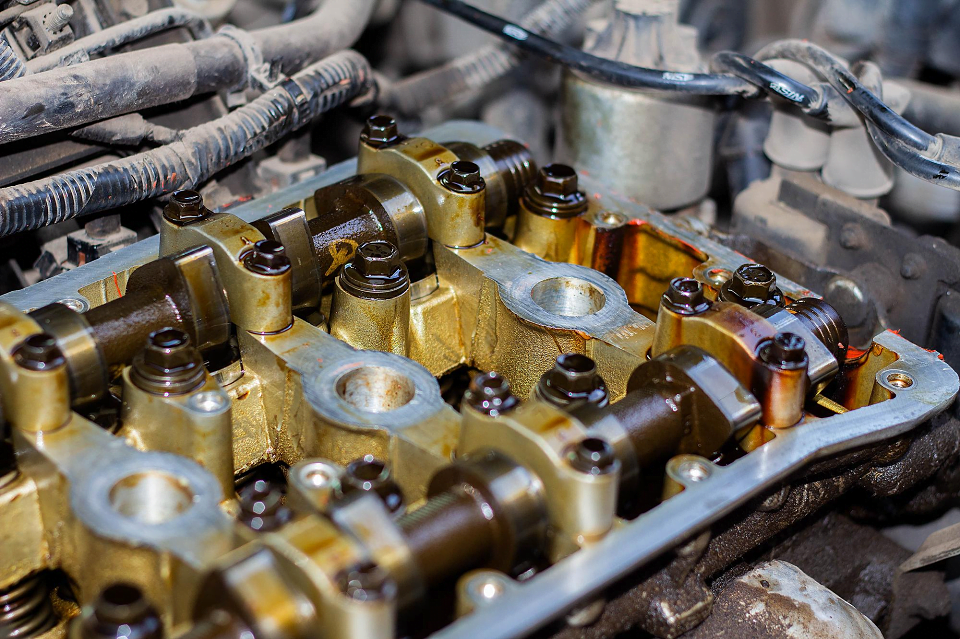

One of the most compelling reasons to utilize brass in automotive manufacturing is its remarkable durability. Brass parts, such as brass rods, brass billets, and brass bars, exhibit superior resistance to wear and tear. Unlike lighter metals like aluminum or copper, brass is highly resistant to damage from tools and heavy items, making it ideal for components that experience significant stress and strain.

Applications in the Automotive Industry:

– Brass Rods and Bars: Used in manufacturing durable engine components and fittings.

– Brass Billets: Employed in creating robust structural parts.

Fire Resistance

Automotive manufacturing requires materials that can withstand extreme temperatures, especially during welding and assembly processes. Brass, known for its fire-resistant properties, excels in this regard. Brass’s ability to withstand high temperatures while maintaining its structural integrity makes it a preferred choice for critical automotive components. The fire resistance of brass ensures that its parts maintain reliability even under the most demanding conditions.

Key Benefits:

– Safety: Enhanced fire resistance contributes to overall vehicle safety.

– Reliability: Brass parts remain robust and intact under high temperatures.

Versatility and Malleability

Brass is an incredibly versatile material, available in various tones and easily adaptable to different automotive design needs. Its malleability allows it to be shaped and contorted without breaking, unlike iron or steel, making it highly adaptable for various automotive applications. This makes brass ideal for creating intricate and custom automotive components. Brass round bars and brass ingots can be precisely shaped into the desired forms, ensuring perfect fits and seamless integration into various vehicle parts.

Examples of Versatile Uses:

– Brass Components: Custom fittings and fixtures that require specific shapes.

– Brass Products: Aesthetic trims and functional parts that need to blend seamlessly with vehicle design.

Corrosion Resistance

Rust and corrosion are significant concerns in the automotive industry, as they can severely impact the longevity and performance of vehicle components. Brass’s natural resistance to corrosion makes it an ideal choice for automotive manufacturers. This property ensures that brass fittings, tubes, and radiator cores remain intact and functional even in harsh environments, preventing premature wear and extending the life of the vehicle.

Specific Applications:

– Brass Tubes: Used in radiator systems to prevent rust and corrosion.

– Brass Radiator Cores: Offer durability and long-lasting performance.

Sustainability and Recycling

Brass stands out for its ability to retain its original properties through repeated recycling processes. This sustainability aspect makes brass an environmentally friendly option, as it lessens the requirement for new raw materials and diminishes environmental impact. Recycled brass ingots and billets not only maintain their chemical and physical properties but also contribute to cost savings and lower greenhouse gas emissions compared to mining new materials.

Environmental Impact:

– Reduced Waste: Diverts brass from landfills, promoting recycling.

– Cost-Effective: Lower production costs and fewer emissions.

Conclusion

For Sneh Metal Alloys, incorporating brass in automotive manufacturing is more than a nod to tradition; it is a strategic decision that delivers numerous advantages. From durability and fire resistance to versatility, corrosion resistance, and sustainability, brass products, including brass parts, brass rods, brass ingots, brass billets, brass bars, and brass round bars, provide unmatched advantages. By integrating brass components into automotive design, manufacturers can ensure robust, reliable, and long-lasting vehicles.

Embracing the benefits of brass, Sneh Metal Alloys remains committed to delivering high-quality brass products that meet the evolving needs of the automotive industry.