Brass Alloy Grades And Properties

The non-ferrous metal known as brass is red in colour and has properties that are comparable to copper’s. Copper and zinc make up the bulk of brass parts, which indicates that this material is an alloy rather than a pure form of metal. Other metals, including lead, tin, iron, aluminium, silicon, and manganese, are added to the mixture in order to produce combinations of characteristics that are even more distinctive than those that were previously possible.

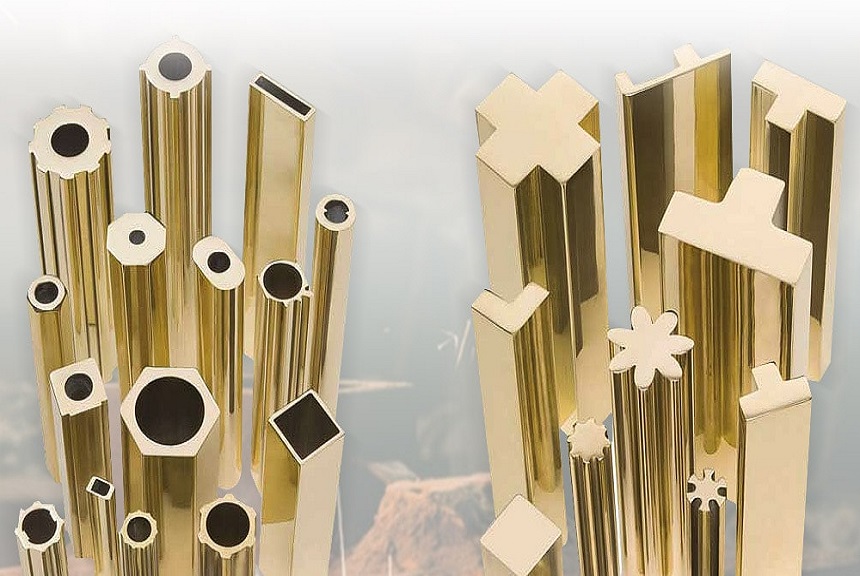

The addition of zinc to the copper substance results in the base copper composition becoming both more durable and ductile. As the percentage of zinc in the alloy rises, its wear resistance improves, and its malleability grows. High-strength brass parts contain zinc which makes up 39% of the element’s total weight. There are several different forms of brass, including rods made of brass alloy, brass components, Brass bars, sheets, tubes, and pipes. Brass can also be found in pipe form.

Brass’s Innate Qualities And Characteristics

Due to the fact that brass is an alloy of copper, it possesses many of the characteristics that are associated with copper. When contrasted with pure copper and many other copper alloys, the alloy does, on the other hand, exhibit a few features that are exclusive to itself. To give only one illustration:

Potential for the development of stress cracks Brass: Because it is stronger and more rigid than pure copper, it has a greater potential for the development of stress cracks.

The malleability and formability: In this brass are superior to those bronze in comparison. Brass may be formed into more intricate shapes. In addition to this, casting and working with it is not difficult.

High Melting Point Brass Components: With a temperature of about 900 degrees Celsius is required for it to completely melt. The precise melting point shifts depending on how many different types of metals are combined to make up the alloy.

Non-ferromagnetic: Brass, which is not ferromagnetic, may be recycled with a great deal less effort than other metals due to the fact that it does not exhibit magnetic properties.

Available Brass Grades

Brass is available in a wide variety of grades, each of which is distinguished from the others solely by the specific elements that make up the material. The following six classes of brass are available for inspection, so let’s have a look at them:

- Alloy 260 possesses advantageous cold working qualities and is also known as cartridge brass. It functions very well in munitions, as well as in other types of fasteners, hardware, and ammunition.

- Zinc constitutes 33 percent of the overall composition of the alloy known as Alloy 272, which also goes by the name yellow brass. In both industrial and architectural contexts, it is used rather frequently.

- Brass alloy 330 is an excellent choice for applications in which it is necessary to have a high level of machinability. Because it contains such a low percentage of lead, it is suitable for cold working and is therefore widely used in the production of pipes.

- Alloy 353 – Due to the outstanding machinability of alloy 353, which is also known as clock brass, it is commonly employed in the manufacturing of accurate components, including parts for clocks and watches.

- This alloy, also known as free-cutting brass, is the most common type of brass and is used in a wide variety of applications. Alloy 360 In addition to being excellent for soldering and brazing operations, it also displays exceptional machinability and formability. It is typically put to use in the fabrication of hardware parts, fittings, valves, and fasteners.

- This type of architectural bronze, which is also known as Alloy 385, can be utilised in the construction industry for a variety of building and construction projects. Extruded and drawn shapes of alloy 385 are readily accessible in a wide variety of configurations, including but not limited to angles, channels, square tubes, handrail moulding, and many other shapes.

- Brass contains lead that has been alloyed to the C48200-C48500 grade range and is designed for use in ship machining. There are numerous opportunities to participate in rounds.

- Alloy 464 is distinguished by its high resistance to corrosion brought on by salt water over a broad temperature range. This property of alloy 464 can be observed in a variety of different environments (also known as naval brass). Moreover, it demonstrates an aptitude for hot forming and hot forming, in addition to drawing, bending, heading, soldering, brazing, and welding.

Concluding

Sneh Metal Alloys was founded in 2016, and since then, the company has established itself as an industry leader in the production, supply, and export of extruded profiles made from non-ferrous metals. Aluminum Bronze Rods, Nickel Silver Wire, Copper Alloy, and Brass components, brass parts, brass bars are just some of the products that may be found on our extensive and ever-growing list of offerings.

We manufacture bars in a variety of shapes, including round, hex, square, and rectangle, as well as hollow and built-to-order shapes, for use in applications that are special to individual customers. In addition to brass bars and brass billets, we also carry a variety of grades of copper alloy ingots and a large selection of brass components to meet the varying requirements of our clientele.