Brass Tube Fitting Advantages

Brass is one of the most popular materials for pipe fittings. Both zinc and copper alloys have been used for hundreds of thousands of years due to the unique properties that make them suitable for various uses. Recently, brass has become commonly used in drains and fittings. Plumbers and other construction experts favor brass fitting for pipes because of their versatility. It is more durable, flexible, and corrosion-resistant than other materials.

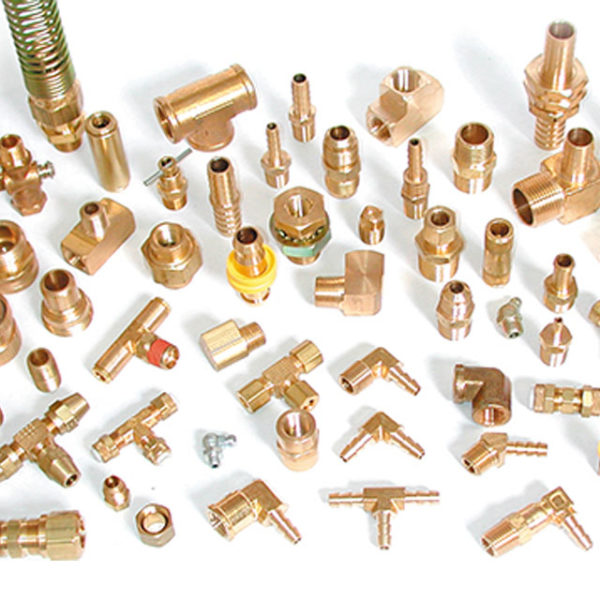

Typically, brass pipe fittings are used to transmit liquids like slurries, chemicals, combustible gases, and water. Brass parts are available in various forms and thread sizes, and they can connect, modify, and ultimately control any gas or liquid in pipes. Brass fittings are used in plumbing, fuel line fittings, air brakes, and other automotive components. Brass is used to making ballcock connectors, fridge coolers, and compression fittings.

What advantages can brass fitting offer?

Given the range of options available, many ponder whether buying brass fitting for waterworks equipment is advantageous. Plumbing fixtures and parts are typically made of this well-known zinc and copper alloy, whether for modest residential structures or big industrial complexes. Plumbing system components made of this metal can be strong and durable. If you want to know how well brass will work in the system, consider these five great benefits as you design the next upgrades or additions.

Versatile fittings are available in various sizes, shapes, and heights because brass may be utilized for various applications. Some fittings can even change the diameter of the tube. Visible brass fitting can be cleaned chrome-plated, nickel-plated, lacquered, or otherwise, given an antique appearance.

Very Durable:

Brass is a very strong metal with several extra desirable characteristics. As they do not break or deteriorate with time, brass pipe connections are a fantastic choice for systems that will last for a long time. Through the distribution pipes, it also provides the hottest water.

Ability to Endure High Temperatures

Brass is the finest material for heated water distribution pipes because it effectively transfers heat and increases system efficiency. Brass is particularly flexible when temperatures rise and can withstand much higher temps than other metals. It is one of the few items that can withstand a large house fire.

Outstanding Corrosion Resistance

The best level of rust resistance is provided by brass, yet other metal fittings may have corrosion issues. The optimum option is a corrosion-free metal, as corrosion and rust can greatly increase how much wear and tear metal components experience. Brass fittings’ best quality is their resistance to corrosion and rust in settings with neutral pH water. In any kind of water, even the most acidic brass won’t corrode.

Extremely malleable Brass is excellent for bending or curving items. Because of this, it is simpler to replace than steel or iron tube. Additionally, it forms superior to the overwhelming majority of rival items. Although the metal is easy to work with, it is highly dependable and robust. Brass is an excellent choice for your system because it won’t rust or get too hot and will survive for many years.

What functions do brass fitting serve?

Among the most used materials for making pipe fittings is brass. Due to their special characteristics, alloys made of zinc and copper have been utilized for thousands of years in various applications. Of course, plumbing fixtures and pipes continue to use brass today. Brass, however, has other use besides pipe fitting, as discussed below.

The most frequent uses for brass are in technical and aesthetic applications. Brass is commonly used in applications that require a low-friction environment because of its unique features, such as corrosion resistance. Tools, utility parts, fixtures, bolts and connections, and ammunition components are among the uses.

Use in Decoration

Decorative brass is often used in ornamental applications due to its aesthetic appeal and antibacterial properties. Its colors could be silver, almost red, or pale gold. It is aesthetically beautiful and microbial-resistant, so brass parts are frequently used for lamp fixtures and home dishwashers.

Applications for Mechanics

Brass scrap and material are frequently used in mechanical applications, from straightforward bearings and gears to the round chambers for the M-16 assault rifle. Brass tools are renowned for having a longer lifespan and requiring less honing.

Used in Music Instruments

You must be familiar with the brass around you if you’ve ever participated in an orchestra, marching band, or symphony. Trombones, baritones, trumpets, French horns, and tubas are the most popular brass instruments. Brass components are quite popularly used in musical instruments.

Brass is a popular material used in pipe fittings, the auto industry, decorative pieces, and musical instruments. You can use brass fitting for your project without considering it. In case you have doubts, you can contact Sneh Metal Alloys which is a brass fitting provider, and learn about other materials useful in water piping solutions.