Guide to Admiralty Brass Tubes: Key Facts and Insights

Brass is one of the major components that contributes to a machine’s strength, is resistant to corrosion, etc. As brass has different varieties, one might get confused about which brass they want to choose that suits the best one as per their specific requirements. To mitigate the confusion, we’re bringing this guide about Admiralty Brass Tubes.

Let’s read more about Admiralty Brass Tubes, their key advantages, and their insights.

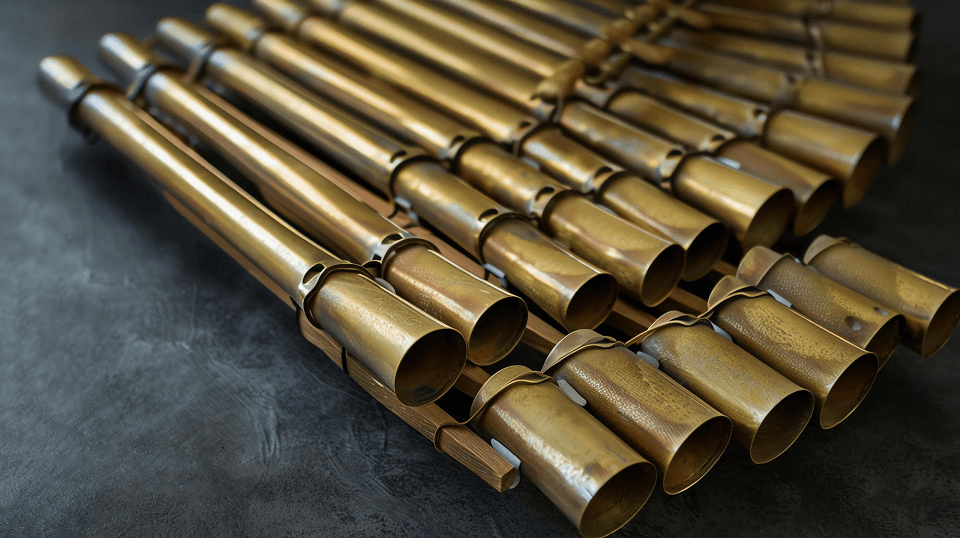

What are Admiralty Brass Tubes?

Admiralty brass alloy is not a pure metal; instead, it has combined different metals like copper, zinc, and tin. If we talk in-depth, then approximately 70% copper is used, 29% zinc, and 1% tin. As admiralty is combined by these all, it has mostly all the traits that these three metals have. Hence, making it a perfect choice for many industries.

While all these components offer some benefits, tin’s 1% contribution surpasses everyone. Tin protects against dezincification, which is a form of corrosion that occurs when zinc leaches out of the alloy, leaving behind a weakened structure. With this specification, it becomes the perfect choice for usage when the tubes are exposed to seawater and a relatable environment.

Properties of Admiralty Brass Tubes

As we read a bit about admiralty brass tubes, now let’s read some more facts about their properties.

- Corrosion resistance: As it is a combination of metals like copper, zinc, and tin, it becomes the best choice when corrosion resistance is majorly required.

- Thermal conductivity: The Admiralty brass tube has the maximum amount of copper and hence offers thermal conductivity without any doubt. For the same reason, it can efficiently transfer heat.

- Strength and durability: If you’re searching for strength and durability, then Admiralty brass tubes offer both of these traits.

- Resistance and dezincification: Admiralty brass has a bit of tin metal that particularly offers dezincification and creates a layer that protects it from corrosion.

- Workability: If we compare all the metals, then admiralty brass tubes are easy to work with. They can be molded into any shape, can be cut, and used in many industries.

- Cost-effective: With all these traits, it is notable that admiralty brass is still a cost-effective option compared to other metals.

Applications of Admiralty Brass Tubes

- Heat exchangers: Now, we know that admiralty brass can efficiently handle heat and is corrosion-resistant. For these two traits, they can be the perfect fit where heated water or steam is involved.

- Condensers: Condensers are used in industrial plants where they convert steam into liquid. As admiralty brass are efficient for this use, they become the best choice for this function.

- Marine application: In marine applications also admiralty brass tubes are suited the best because of their higher corrosion-resistant quality.

- Power plants: In this industry, admiralty brass tubes are also efficient as they offer thermal conductivity as well as are important components for cooling systems.

- HVAC systems: For its durability and heat conductivity, it is also used in heating, cooling or ventilation systems.

- Oil and gas industry: Admiralty brass tubes have distinctive features like withstanding harsh environment and longevity. For these two features, it is used widely in the gas and oil industries.

Because of its distinctive features, brass tubes are used in the above-mentioned industries.

As we have read everything, now let’s read about how to choose the perfect brass tubes as per your requirements.

- Application requirements: Every component has different application requirements, and based on that, you’ve to find the perfect metal. While choosing admiralty brass tubes, take care of the temperature they will be exposed to, the environment, etc.

- Dimensions: While selecting anything, make sure that you choose the tube as per the perfect dimension and size.

- Quality standards: Make sure the tubes you are buying are perfect as per the industry standards.

- Supplier reputation: First, know everything about the items he sells, and if you find everything trustworthy, then only choose to buy from that store.

Conclusion

We do understand that choosing the right brass alloys is a difficult task. But with the right guidance, we do make it easier. Sharing the key advantages of using Admiralty brass tubes as well as where they can be used, we hope we have made things a bit easier. If you are still confused, then you can always drop a message to Sneh Metals, and we will be more than happy to assist you regarding brass metalworks, choosing the right brass alloys, etc.