Key Advantages of Using Brass Inserts

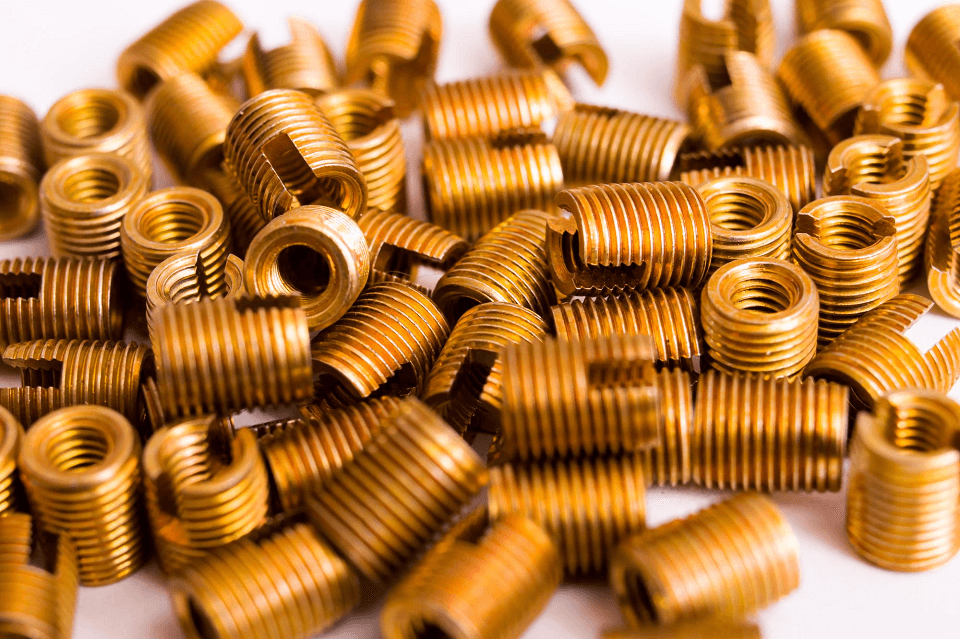

Brass is one of the key components used for its versatility and durability across many industries. One can mold brass in different forms, and hence it is useful for many industries. By adding brass to different components, you can add another layer of strength, robustness, and usability. At Sneh Metals, we make different kinds of brass alloys that fit perfectly as per your specifications. We have been in the brass industry for a long time and have delivered many products and attained user satisfaction.

Let’s delve deeper and learn about the key advantages of brass inserts.

- Long-lasting Threads: Usually brass inserts are used in materials like metal, plastic, or wood to create strong threads that won’t break easily. As brass inserts are in the threads, they become strong and secure, and hence they won’t break easily or wear out in time. Because of brass, all parts are tightly connected, as well as they keep the damage at bay.

- Corrosion Resistance: Brass is famous for its corrosion resistance ability. For this trait, brass components are used in many industries. Because of the high corrosion when brass is exposed to moisture or harsh weather, brass is more resistant to rust and damage than other materials. This quality ensures that your machine stays up to date even in the harsh weather conditions.

- Temperature Resistance: Brass has a great feature in that it conducts heat efficiently. Hence, it proves to be the best component in situations when there is constant contact with heat. Brass can control the temperature or overheating. i.e., it works the best in machines that are constantly used for heating, like welding machines, etc.

- Adaptable Methods of Installation: Brass is one of the only components that is easy to install through different installation processes. It can be installed through press-fitting, heat, or ultrasonic technology. This benefit offers the liberty for manufacturers to choose their installation method. This trait of brass inserts saves time and money during the fittings and still proves to be the strongest metal.

- Aesthetic Improvements: Brass inserts are strong, corrosion-resistant, and many other things, but these are all practical advantages. But you will be shocked when you know brass is best to maintain the aesthetics of your components. Yes, brass inserts work practically as well as aesthetically too. As they can be installed flush with the surface, they offer a smooth, clean appearance without harming the aesthetics.

- Electricity Conduction: Brass is a great conductor of electricity; hence it becomes perfect for electrical components and connections. Brass is not only strong and reliable and protects from heat but is also best when it comes to corrosion resistance and long-lasting durability.

- Broad Spectrum of Uses: Because of their versatility and durability, brass components are used in automobiles, electronics, airplanes, and everyday products. Because of the various traits, they can be used to connect electronic devices, providing strong parts in cars. Also, because of their aesthetic appearance, they are used in home decor too. With all these features, brass inserts offer a broad spectrum of uses.

Conclusion

With all these key advantages, brass stands apart from all the other alloys and components. Because of these distinguished features, brass components are used in many industries. Not only does brass make your machines stronger than ever, but it also maintains the aesthetic of machines as well. At Sneh Metals, you will find a variety of brass alloys as per your specifications. Visit us today and get the brass alloy that fits perfectly for your requirements.