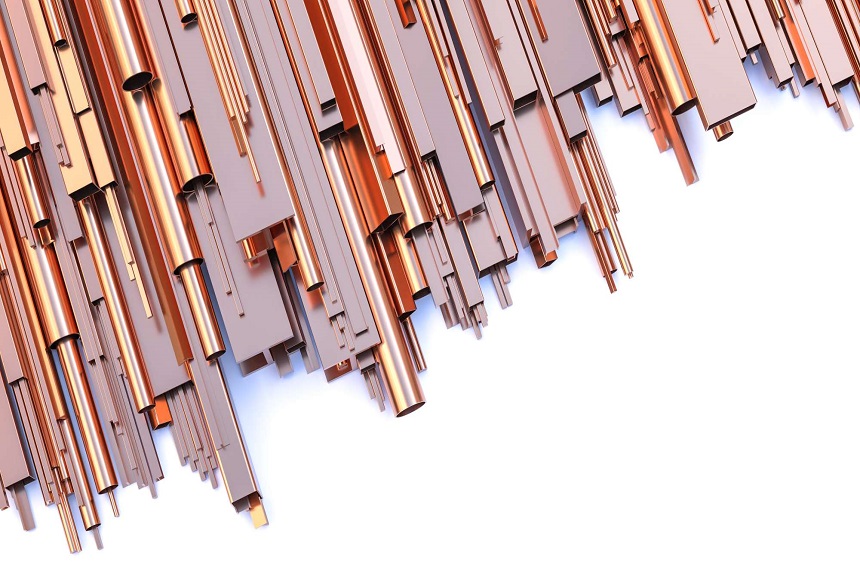

Learn About Copper Bars Best Advantages

Little chunks of metal called copper bars are offered in large quantities. They provide a wide range of functions. For applications involving earthing, for instance, they work brilliantly. Rapid bending and shaping of copper bars are possible. Furthermore, it possesses exceptional anti-cracking and dimensional control qualities.

We at Sneh metals provide copper products, copper alloy ingots, brass components and aluminium ingots of high quality at competitive prices.

Hard-drawn, rectangular, alloy 110 bars with square edges are the most prevalent form of copper bars. Also known as bus bars and ETP copper bars, these are. They have strong thermal and electrical conductivity and are frequently used in the plumbing and building sectors. They also have other electrical uses, like jewellery.

Why Are Copper Bars Beneficial?

Many different products use copper bars for a variety of purposes. Excellent thermal and electrical conductivity go hand in hand with its strong malleability. Furthermore, it is resistant to biofouling and appropriate for use in piping systems for both internal and external activities. It is highly regarded by businesses that produce goods because of these qualities. Moreover, they have outstanding dimensional stability and anti-cracking capabilities and can withstand a variety of conditions.

How Are Copper Bars Used?

Under challenging conditions, copper bars work well. In industries where corrosion resistance is needed, copper round bars are frequently employed. Copper bars and rods have excellent formability qualities, making it simple to bend and turn them. This eliminates the requirement for fittings, cutting the cost.

Because they stop bacterial growth and shield you from UV rays, copper round bars are far preferable to many other solutions. Continually reliable, durable, and affordable are copper bars and rods.

In many different sectors, copper bars are used and in high demand. Examples include machinery used in the chemical industry, oil and gas refineries, pharmaceutical companies, many home appliances, power plants, industrial machinery, and many more applications.

Applications Of Copper Bars In Industries

Copper and copper bars are both appropriate for use in a wide variety of industries because of their many qualities and capabilities. Copper bars have a wide range of applications across a variety of sectors for the following reasons:

– The Built Environment, Specifically Architecture And Building

Copper bars are beneficial to the architectural and construction industries due to the metal’s exceptional resistance to corrosion. In addition to this, copper bars demonstrate excellent resistance to oxide coating and provide longevity. In addition, copper bars exhibit a lower level of corrosion when exposed to air, water, and particles of dust. Copper bars have a number of applications, one of which is roofing.

– Automobile

Copper bars are utilised by the automotive industry to switch out aluminium rotors for copper rotors. The efficiency of electric and hybrid-electric cars is improved when copper bars are present in the battery pack. Copper bars do two more things: they cut down on electric losses and increase the motor’s overall efficiency.

– Applications In The Field Of Electricity

Copper is an excellent conductor of electricity and may therefore be utilised in a wide variety of electrical applications. Copper bars are chosen because of their ability to continue functioning normally while being subjected to greater temperatures and because they provide an additional layer of protection in the event of a short circuit.

– Marine Equipment

In the presence of chlorines and other highly reactive compounds, copper bars have a good ability to resist corrosion. Copper bars are not only resistant to biofouling but also excellent for use in saltwater environments. Copper bars are a good choice for the pipe system that transports seawater, as well as for fuel lines and nails.

– HVAC

Copper bars have a significant potential to adversely alter the quality of the air inside. Copper bars, when used in conjunction with a variety of heating and ventilation systems, have the ability to eradicate harmful germs and infectious microbes.

– Components That Have Been Machined And Cnc Parts

Copper bars are widely accessible and inexpensive despite their status as the best conductors of electricity. In addition, the use of these bars makes the CNC machining process smooth and easy to operate. Copper is resistant to corrosion and can be easily shaped through a variety of processes. Copper is also easy to work with. Machines made out of copper are less likely to become rusted.

Conclusion:

In addition to brass components, and aluminium base ingots of the same size, we create copper alloy ingots with dimensions of 12 inches by 12 inches by 3 inches. Available Sizes for metal ingots: As per your Need.